PRODUCTS

About Us

Company established in 2019

10 million of registered capital

Covering an area of more than 40000 ㎡

Guizhou Senrui Pipeline Development Co., Ltd.

Guizhou Senrui Pipeline Development Co., Ltd. is located in Wudang Economic Development Zone, Guiyang City, covering an area of more than 40000 square meters. It is the largest new environmental protection technology enterprise specializing in the research and development, manufacturing and sales of new plastic pipes in Guizhou Province.

Corporate culture: honesty, pragmatism, learning and innovation

Quality policy: to provide environmental protection, energy saving, safety, economic plastic pipe system

Mission: to improve and enhance the human living environment, to create a green and healthy living space

Business philosophy: survival by quality, development by service, and win-win by integrity

Environmental protection concept: "make the city more beautiful, make life better", "protect the hometown environment, build a better home"

APPLICATION

Guizhou Senrui Pipeline Development Co., Ltd.

The company adheres to the quality concept of "taking science and technology as the guide, regarding quality as life", adhering to the quality concept of "no production of defective products, no outflow of defective products", and strictly controls product quality in accordance with national standards, industry standards and enterprise standards. And the use of a complete physical laboratory for accurate testing of the physical properties of the product.

Our quality

The company insists on customer-centered, internal quality management, external market development, and constantly improve the quality of products and services to meet customer requirements.

Our technology

NEWS CENTER

News Center

An important guarantee for fire safety - special fire protection line pipes

Fires often occur in our lives. To minimize the occurrence of fires and to enable quick and effective rescue during a fire, fire-specific fire-resistant pipes have become an indispensable safety facility. So, what are fire-specific fire-resistant pipes? What is their function? Fire-specific fire-resistant pipes are specially designed for firefighting systems, featuring properties such as fire resistance, heat resistance, and corrosion resistance. During a fire, they can effectively protect the safe transport of firefighting water and equipment, providing firefighters with a reliable rescue channel, thereby ensuring the safety of people's lives and property. Fire-specific fire-resistant pipes have the following characteristics. First, they have strong fire resistance; they can maintain the integrity and stability of the pipes in high-temperature environments, effectively preventing the spread of fires. Second, they have good corrosion resistance; these pipes can withstand various chemical substances' erosion, ensuring their service life. Third, they are high-strength; they can bear significant pressure and weight, ensuring safe operation. Fourth, they are easy to install; these pipes are convenient to operate and can be installed quickly, saving time and labor. Today, there are also many types of fire-specific fire-resistant pipes available on the market. For example, classified by material, they can be divided into steel pipes, cast iron pipes, plastic pipes, etc.; classified by use, they can be divided into indoor and outdoor types. Indoor pipes are generally used for firefighting systems within buildings while outdoor pipes are typically used for firefighting systems outside buildings. In specific applications, fire-specific fire-resistant pipes also have a wide range of usage scenarios. Inside buildings, these pipes are widely used in stairwells, corridors, lobbies, etc., to transport firefighting water and equipment to ensure that personnel can quickly initiate rescue efforts during a fire. They provide firefighters with reliable rescue channels to swiftly deliver firefighting equipment and water to the scene of a fire effectively controlling its spread. At the same time, their strong fire resistance allows them to maintain integrity and stability in high-temperature environments to prevent fires from spreading to other areas.

2024-12-08

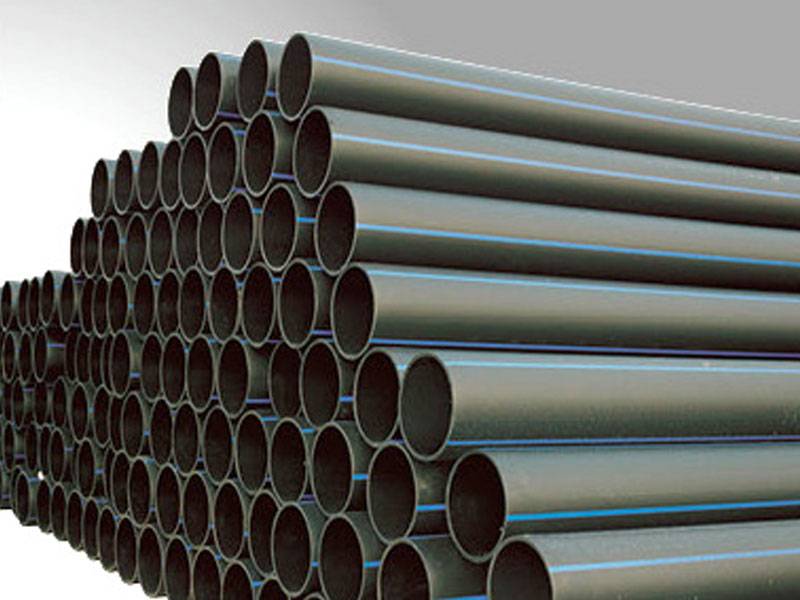

Water supply pipes are a type of pipeline used for transporting water supply, and they are essential facilities in homes, factories, cities, and other places. Water supply pipes play an important role in the water supply system; they need to withstand pressure and flow from the water supply system while also possessing characteristics such as corrosion resistance, wear resistance, and high-temperature resistance to ensure stable water quality and safe water supply. There are many types of water supply pipes, which can be divided into two main categories based on material and purpose: metal pipes and plastic pipes. Metal pipes include galvanized pipes, copper pipes, etc., which have advantages such as high strength, stable performance, and corrosion resistance. However, they also have some drawbacks like being heavy, prone to rusting, and aging. Plastic pipes include PVC pipes, PE pipes, etc., which have advantages such as lightweight, attractive appearance, and ease of construction but also have some disadvantages like relatively low strength and susceptibility to aging. When choosing water supply pipes, it is necessary to select according to different usage scenarios and actual needs. For example, in households, PPR water supply pipes are generally used because they have advantages such as high-temperature resistance, pressure resistance, and corrosion resistance while being relatively affordable. In factories, metal water supply pipes are generally used due to their higher strength and corrosion resistance. In urban water supply systems, PE water supply pipes are commonly used because they offer advantages like corrosion resistance, wear resistance, long lifespan while being relatively inexpensive. The specific performance characteristics of PE water supply pipes can be summarized as follows: 1. Long service life: Under normal use conditions, the lifespan reaches at least 50 years. 2. Good hygiene: PE pipes do not contain heavy metal additives; they do not easily scale or breed bacteria solving the problem of drinking water pollution. 3. Strong corrosion resistance against various chemicals. 4. Smooth inner wall with extremely low friction coefficient allowing smooth passage of media while having excellent wear resistance. 5. Good flexibility leading to excellent impact resistance; able to recover after strong shocks or twists. 6. Lightweight making transportation and installation convenient. 7. Unique electric fusion connection and hot melt socket connection methods ensure that the joint adhesion strength is higher than that of the pipe body; joints will not break due to soil movement ensuring reliable connection at interfaces. 8. Simple welding process with easy construction resulting in low overall project costs.

2024-12-08

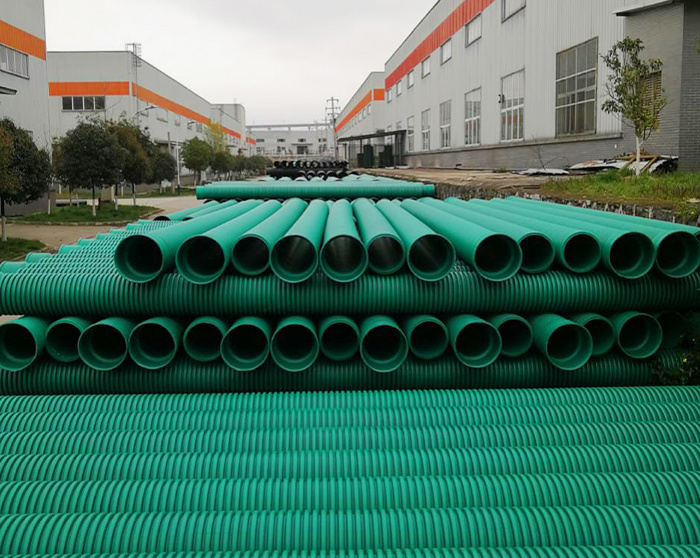

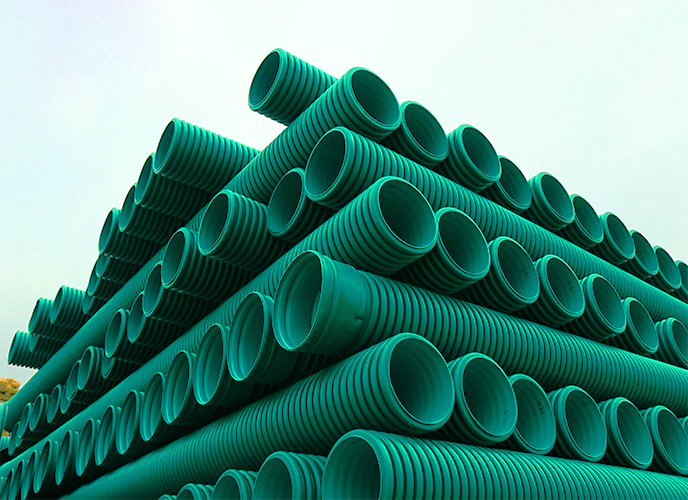

Nine Major Advantages of HDPE Double-Wall Corrugated Pipe

HDPE double-wall corrugated pipe, also known as PE corrugated pipe, has an outer layer typically made of high-density polyethylene (HDPE) and an inner layer made of corrosion-resistant materials such as metal or special plastics. The space between these two layers is corrugated, which is also the reason for its name. Compared to traditional concrete pipes and cast iron pipelines, HDPE double-wall corrugated pipes are very lightweight, have excellent chemical and physical properties, and are very convenient to connect with simple construction. It mainly has the following major advantages: 1. Strong compressive strength; due to its unique structure, HDPE pipes have strong compressive strength and impact resistance. 2. Good flexibility; this means that HDPE double-wall corrugated pipes can adapt to uneven soil settlement environments, have low requirements for construction conditions, and can be laid in non-straight trenches. 3. Smooth inner wall; easy for liquid transportation with a large flow capacity, reducing transport pressure. 4. Lightweight; easy to transport and construct, which also means lower construction costs and shorter construction periods. 5. Better wear resistance; German experiments have shown that HDPE pipes have 3-5 times better wear resistance than ordinary or fine-grained steel pipes when transporting fluids at a speed of 15 feet per second. 6. Convenient connections; zero leakage at joints, corrosion-resistant, good sealing properties, no scaling occurs, avoiding secondary pollution of water quality during transportation without worrying about the flow area being reduced due to scaling issues. 7. Long lifespan; the service life exceeds that of traditional steel pipes and can reach over 50 years under conditions without strong ultraviolet exposure. 8. Stable chemical properties; because HDPE molecules are non-polar, most chemical media will not damage it except for a few strong oxidizers. Under normal environmental conditions such as electricity, soil, and conventional acids and bases will not damage HDPE double-wall corrugated pipes and are less likely to breed bacteria. 9. Low-temperature resistance; the embrittlement temperature of HDPE double-wall corrugated pipes is -70°C, so there is no need for special protective measures during construction under general low-temperature conditions (above -30°C), making winter construction convenient.

2024-12-08

What are the standards for water pipes?

The standards for water supply pipes are directly related to water quality safety and the long-term stability of the pipeline system. According to national standards such as "Polyvinyl Chloride (PVC-U) Pipes and Fittings for Water Supply" (GB/T 13663) and "High-Density Polyethylene (HDPE) Pipes and Fittings for Water Supply" (GB/T 13663), water supply pipes must meet strict quality requirements to ensure that they do not affect water quality during long-term use and are not influenced by environmental factors.

2024-12-08

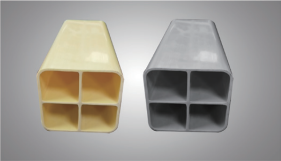

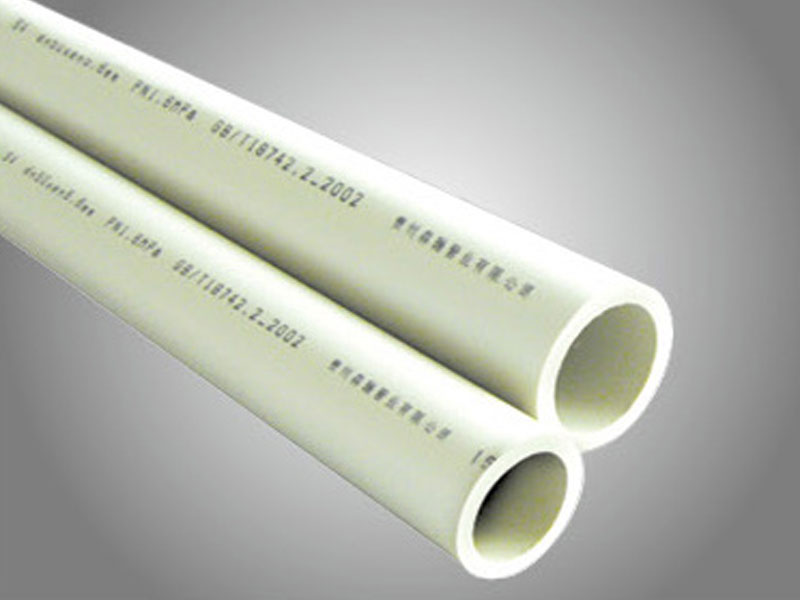

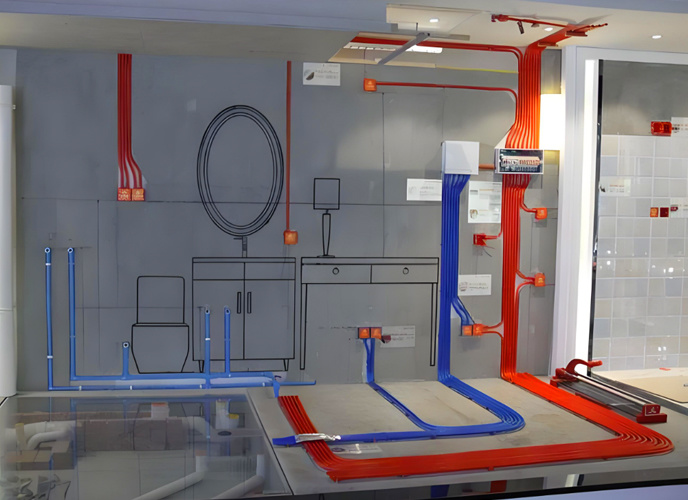

Premium home decoration PP-R healthy water supply pipe

Senrui Boutique Home Decoration PP-R Environmental Health Water Supply Pipe System introduces advanced technologies and processes from both domestic and international sources. It is a new type of home decoration product completed through the joint efforts of our company's professional product designers and technical personnel. Based on references to well-known domestic and international brands, it is designed with Chinese cultural characteristics, featuring an aesthetically pleasing, simple, and elegant appearance. The unique reinforced decorative design serves as a reference for vertical alignment during installation while enhancing the strength and stability of the fittings, making them less prone to damage and eliminating the risk of leaks. It also improves the aesthetic appearance of the fittings, compensating for the shortcomings of ordinary PP-R fittings. In terms of quality, Senrui Boutique Home Decoration PP-R Environmental Health Water Supply Pipe Series products are strictly produced according to ISO9001 quality management standards, fully complying with GB/T18742.1, GB/T18742.2, GB/T18742.3 as well as GB/T17219 hygiene standards and relevant health safety evaluation regulations from the Ministry of Health. Its comprehensive technical performance indicators and economic indicators far exceed those of other similar products. With advantages such as heat resistance, pressure resistance, safety, energy saving, environmental protection, economy, and long service life, it has gradually replaced existing types of water pipes to become the leading product in home decoration piping.

2024-12-08