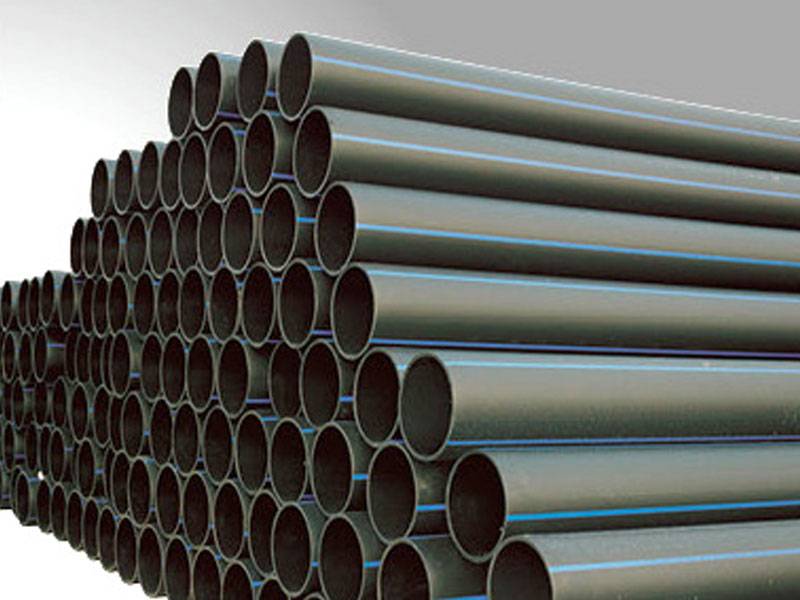

PE safety gas pipe

PE safety gas pipes have excellent properties such as long service life, good flexibility, resistance to crustal settlement, corrosion resistance, and resistance to slow and rapid crack propagation. The pipeline system adopts connection methods such as hot melt docking and electric melting, and the pipes and fittings are fused into one. The system is safe and reliable, and the construction cost is low.

Classification:

Detailed description

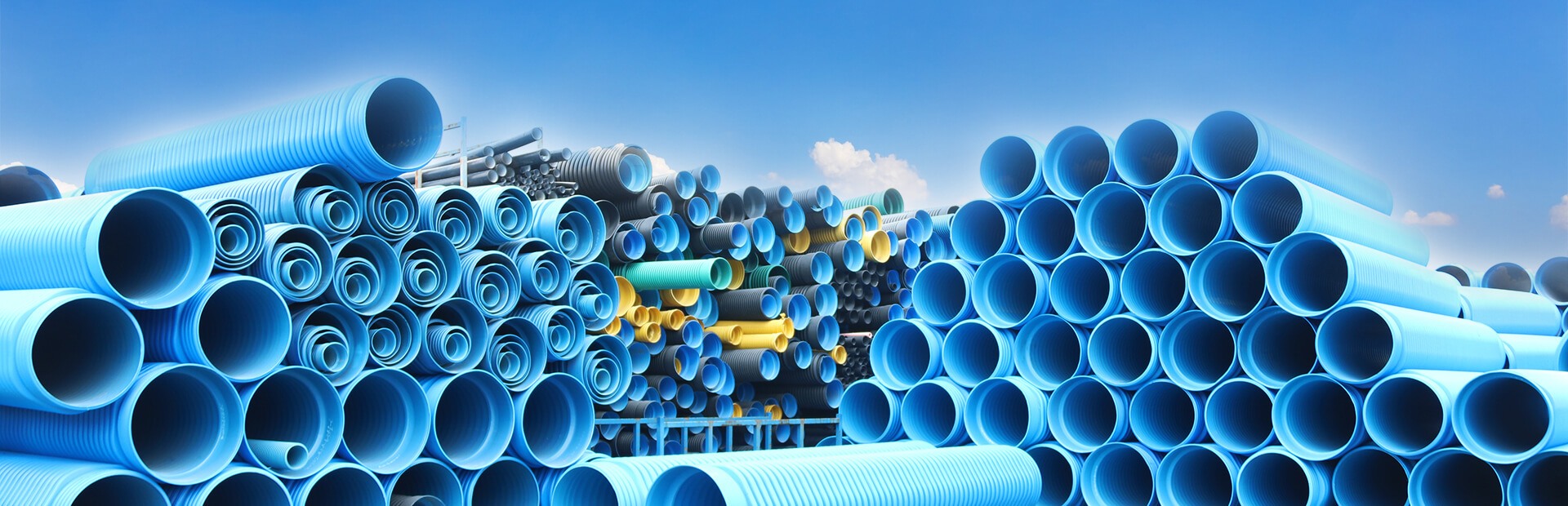

Product Introduction

Our company uses the best German KraussMaffei and Battenfeld pipe extrusion production lines available internationally, insisting on selecting PE100 and PE80 gas-specific polyethylene blends from Nordic Chemical, continuously optimizing production processes, and improving employee operational skills and quality. This ensures that the gas pipes maintain the excellent physical and mechanical properties of the raw materials to the greatest extent. A scientifically standardized management system achieves traceability of product quality from raw materials to engineering applications; an independently equipped German iNOEX metering and weighing system, along with an ultrasonic online diameter and thickness measurement system, ensures zero defects and consistently high quality for Senrui gas pipes.

PE safety gas pipes comply with GB 15558.1-2003 standards, featuring a long service life, good flexibility, resistance to ground subsidence, corrosion resistance, and excellent performance against slow crack propagation and rapid crack propagation. The pipeline system employs heat fusion and electrofusion connections, integrating pipes and fittings into one system that is safe and reliable, with low construction costs. The promotion of PE gas safety pipelines aligns with national guidelines for the development of chemical building materials and meets the developmental needs of improving living standards.

Product Features

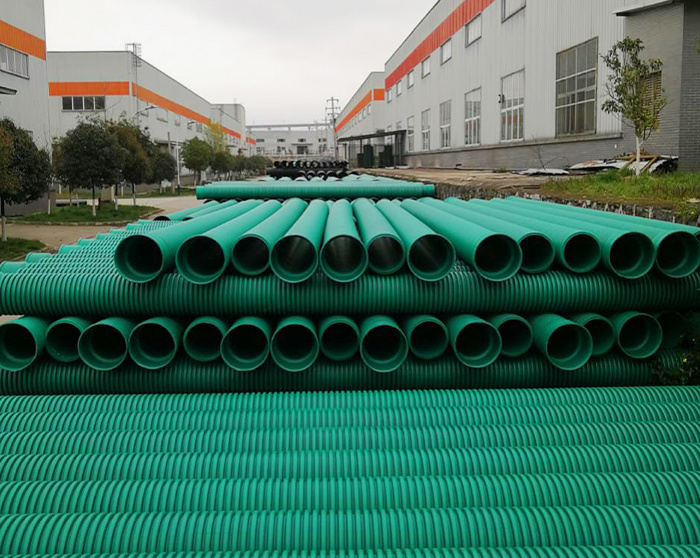

◎ Lightweight, easy to transport and unload; good flexibility with excellent impact resistance. The pipeline can deform under external impacts without affecting its operation and can recover. Flexible pipelines can achieve 'joint action of pipe and soil', effectively ensuring pipeline safety; excellent corrosion resistance. The pipeline is not affected by external acids, alkalis, salts, etc. The inner wall is free from scaling, ensuring smooth transportation;

◎ Safe and reliable connections. Using heat fusion or electrofusion connections forms a homogeneous connection system that is tight, easy to construct, lightweight pipes reduce labor intensity during construction, effectively shortening construction time and reducing costs; long service life with a normal lifespan of 50 years.

Main Application Areas of the Product

◎ Underground polyethylene (PE) pipelines for gas are suitable for working temperatures between -20~40°C and a long-term maximum working pressure not exceeding 0.7MPa for gas transmission pipeline systems.

Key words:

Senrui pipeline, Guiyang pipeline manufacturer

Related Products

Complaint recommendations

Note: Please fill in the above information correctly so that we can feedback the processing results to you at the first time!