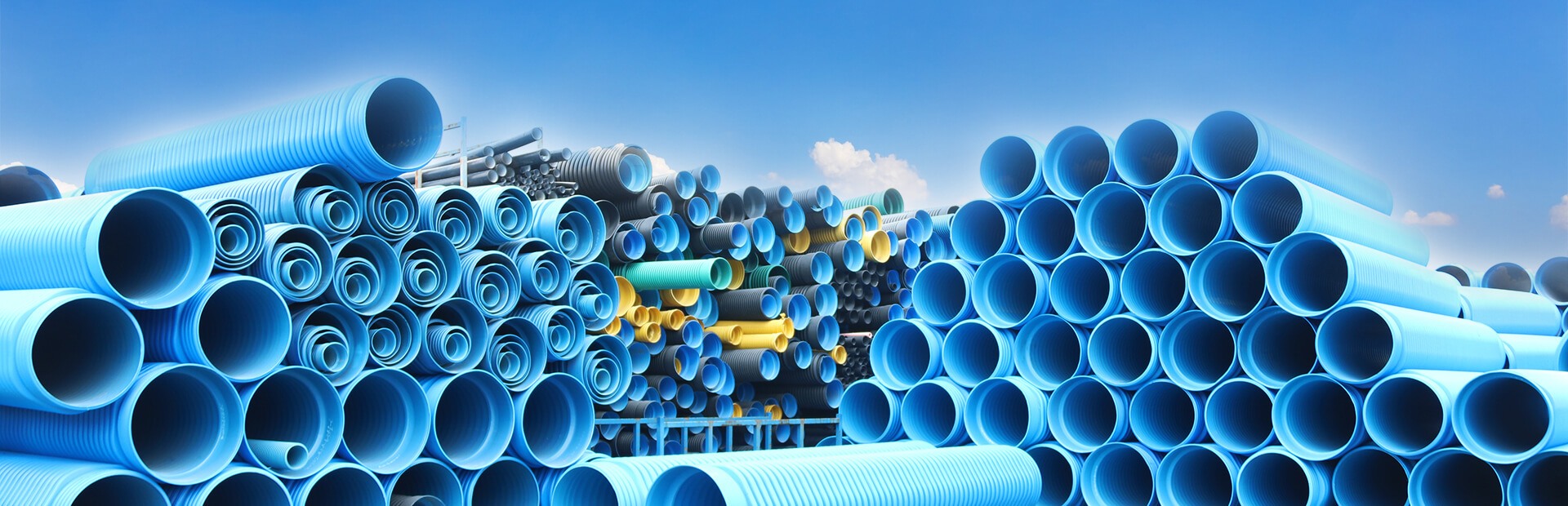

Buried modified high-density polyethylene (HDPE-M) double-wall corrugated pipe

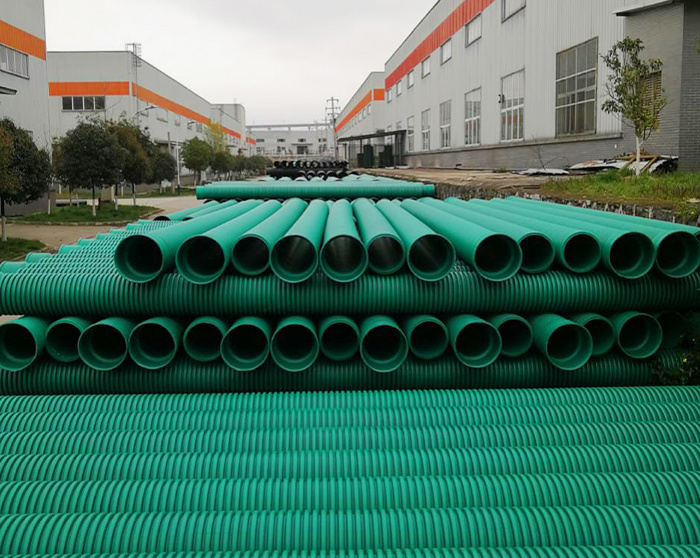

The buried modified high-density polyethylene (HDPE-M) double-wall corrugated pipe is suitable for underground drainage, sewage, and other projects with a long-term working temperature of 45°C and below.

Classification:

Detailed description

Product Application Scope

Buried modified high-density polyethylene (HDPE-M) double-wall corrugated pipe is suitable for underground drainage, sewage, and other projects with a long-term working temperature of 45°C and below.

Implementation Standard: T/CECS 10022-2019

Product Structure / Connection Method

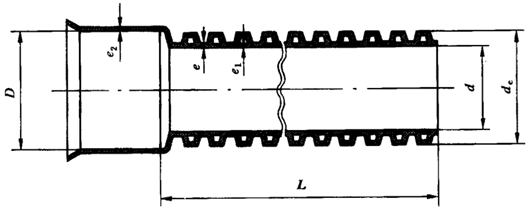

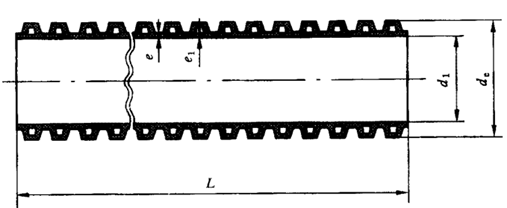

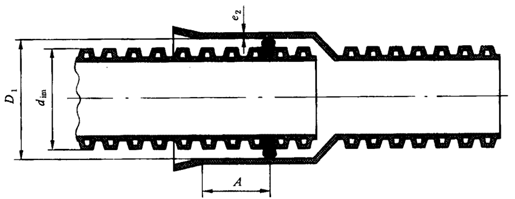

Product Structure: A typical structure is shown in the figure.

Product Connection Method: Pipes should generally be connected using a socket method with an elastic sealing ring, as shown in the typical connection method.

Technical Requirements:

Color: The color of the inner and outer layers of the pipe should be uniform and consistent, with the outer layer preferably being colored; specific colors can be agreed upon by both parties.

Appearance: The inner and outer walls of the pipe should not have bubbles, dents, obvious impurities, or irregular corrugations. The two ends of the pipe should be flat, perpendicular to the axis, and located in the trough area. The inner and outer walls in the trough area of the pipe should be tightly fused without separation.

Specification Size: The pipe specifications are indicated by nominal inner diameter (DN/ID).

Length: The effective length of the pipe should be 6m; other lengths can be determined through negotiation between both parties, and there should be no negative deviation in length.

Size: The dimensions of the pipe should meet the requirements in the table below.

Unit: Millimeters.

Note: The average inner diameter, laminated wall thickness, inner wall thickness, joint length, and socket wall thickness in the table are all minimum dimensions.

Physical and Mechanical Properties: The physical and mechanical properties of the pipe should meet the specifications in the table below.

Physical and Mechanical Properties of the Pipe

| Serial Number | Item | Index | Test Method | Ring Stiffness (kN/m²) | (SN8) |

| 200 | 195 | 1.5 | 1.1 | 60 | 1.8 |

| 300 | 294 | 2.0 | 1.7 | 69 | 2.3 |

| 400 | 392 | 2.5 | 2.3 | 77 | 2.9 |

| 500 | 490 | 3.0 | 3.0 | 85 | 3.5 |

| 600 | 588 | 3.5 | 3.5 | 96 | 4.0 |

| 800 | 785 | 4.5 | 4.5 | 118 | 5.3 |

| 1000 | 985 | 5.0 | 5.0 | 140 | 5.9 |

| 1200 | 1185 | 5.0 | 5.0 | 162 | 5.9 |

| 1500 | 1485 | 6.0 | 5.0 | 178 | 5.9 |

| ≥ 8 | |||||

≥ 12.5

≥ 16

| ≥ 20 | Impact Performance (TIR) (%) | ≤ 10 | Ring Flexibility | |

| 1 | Sample is smooth, no reverse bending, no cracking, no separation between walls. | Oven Test | No bubbles, no delamination, no cracking. | 9.4.1 |

| SN12.5 | Creep Ratio (%) | |||

| SN16 | ≤ 4 | |||

| SN20 | Oxidation Induction Time (OIT) (min) | |||

| 2 | Note: The values in parentheses are non-preferred ring stiffness grades. | Use measuring instruments with a minimum scale not greater than 0.1% of the measured value to measure two inner diameters at right angles on the same cross-section of the pipe; use the arithmetic average of the two inner diameters as the average inner diameter of the pipe. | 9.4.2 | |

| 3 | 环柔性 | 试样圆滑,无反向弯曲,无破裂,两壁无脱开 | 9.4.3 | |

| 4 | 烘箱试验 | 无气泡、无分层、无开裂 | 9.4.4 | |

| 5 | 蠕变比率(%) | ≤ 4 | 9.4.5 | |

| 6 | 氧化诱导时间(OIT)(min) | Oxidation Induction Time (OIT) (min) | 9.4.6 | |

| 注:括号内数值为非首选的环刚度等级。 | ||||

用最小刻度不大于被测值 0.1% 的量具分别测量管材同一断面相互垂直的两内径,以两内径的算术平均值作为管材的平均内径。

Key words:

Senrui pipeline, Guiyang pipeline manufacturer

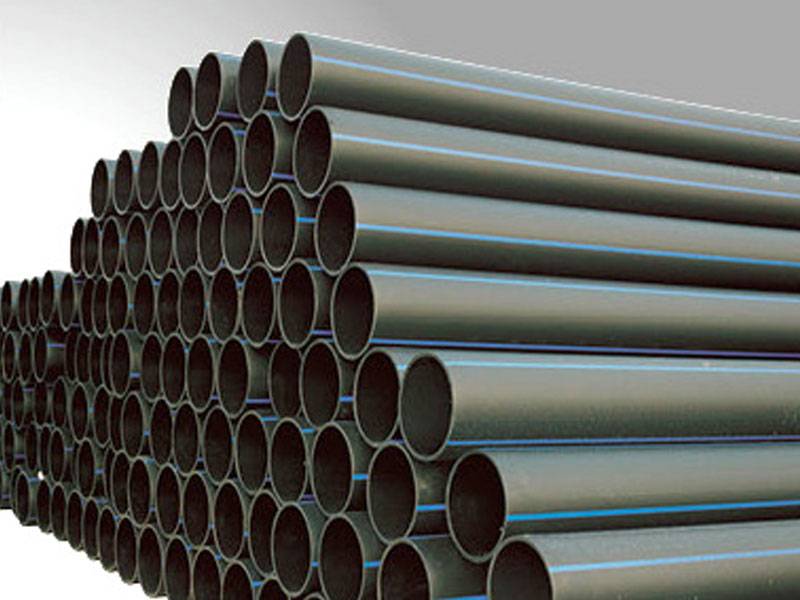

Related Products

Complaint recommendations

Note: Please fill in the above information correctly so that we can feedback the processing results to you at the first time!