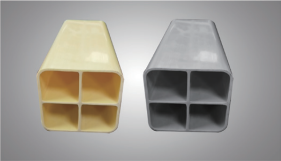

Buried PVC-C power cable protection conduit

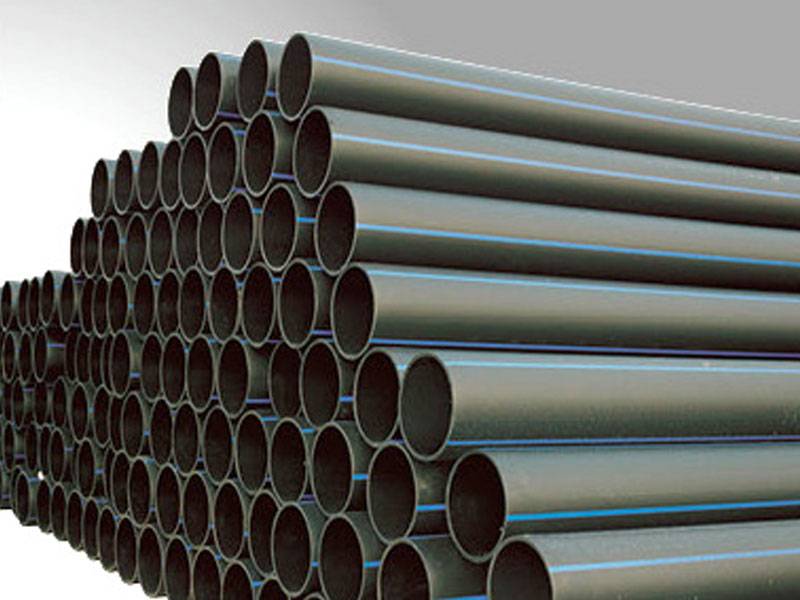

Buried high-voltage power cable PVC conduit is a modified PVC-C pipe with special physical properties, made primarily from high-temperature resistant chlorinated polyvinyl chloride resin, with necessary additives included and extruded into shape. This product is mainly used for the laying of high-voltage power cables, serving to guide and protect the cables, and is increasingly used in domestic power engineering.

Classification:

Detailed description

Product Introduction

The underground high-voltage power cable PVC casing is a modified PVC-C pipe with special physical properties, primarily made from high-temperature resistant chlorinated polyvinyl chloride resin, with necessary additives added and extruded into shape. This product is mainly used for the laying of high-voltage power cables, serving to guide and protect the cables, and is increasingly used in domestic power engineering.

Product Features

◎ Good flexibility, high temperature resistance, not easy to break or age, with a long service life, no radiation pollution, lightweight, etc. It uses a bell-mouth socket connection for easy installation and low project costs;

◎ Excellent heat resistance: The core temperature of high-voltage power cables varies with the voltage during normal operation. For example, the core temperature of a cable transmitting 110KV voltage reaches the casing at 65℃ under normal conditions and can reach 75℃ under overload conditions. PVC-C material has a thermal deformation temperature of up to 93℃, suitable for high-temperature environments;

◎ Good insulation properties, volume resistivity ≥ 1.0×10^11Ω.m;

◎ Excellent flame retardancy, oxygen index ≥ 40;

◎ Strong corrosion resistance;

◎ Uses bell-mouth socket bonding for easy installation and low project costs.

Main Application Areas of the Product

◎ This product is mainly used for underground installation of 110 kV high-voltage and ultra-high-voltage cables or streetlight cables.

PVC-C Power Pipe Specifications

| Nominal Outer Diameter (mm) | Wall Thickness (mm) | Effective Length |

| 50 | 2.5 | 6000mm |

| 50 | 3.0 | 6000mm |

| 50 | 5.0 | 6000mm |

| 63 | 3.0 | 6000mm |

| 63 | 5.0 | 6000mm |

| 75 | 3.0 | 6000mm |

| 75 | 5.0 | 6000mm |

| 90 | 3.0 | 6000mm |

| 90 | 4.0 | 6000mm |

| 90 | 5.0 | 6000mm |

| 110 | 3.0 | 6000mm |

| 110 | 4.2 | 6000mm |

| 110 | 5.0 | 6000mm |

| 125 | 5.0 | 6000mm |

| 125 | 8.0 | 6000mm |

| 156 | 3.0 | 6000mm |

| 160 | 3.2 | 6000mm |

| 160 | 4.2 | 6000mm |

| 160 | 4.5 | 6000mm |

| 160 | 5.0 | 6000mm |

| 162 | 6.0 | 6000mm |

| 167 | 5.0 | 6000mm |

| 167 | 8.0 | 6000mm |

| 167 | 7.0 | 6000mm |

| 167 | 8.5 | 6000mm |

| 181 | 3.0 | 6000mm |

| 181 | 7.0 | 6000mm |

| 200 | 3.9 | 6000mm |

| 200 | 5.0 | 6000mm |

| 200 | 7.0 | 6000mm |

| 200 | 8.0 | 6000mm |

| 200 | 10.0 | 6000mm |

| 219 | 9.5 | 6000mm |

Key words:

Senrui pipeline, Guiyang pipeline manufacturer

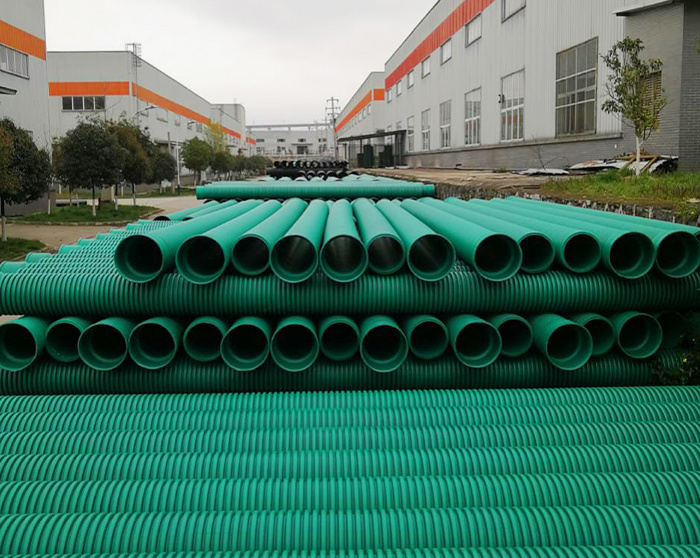

Related Products

Complaint recommendations

Note: Please fill in the above information correctly so that we can feedback the processing results to you at the first time!