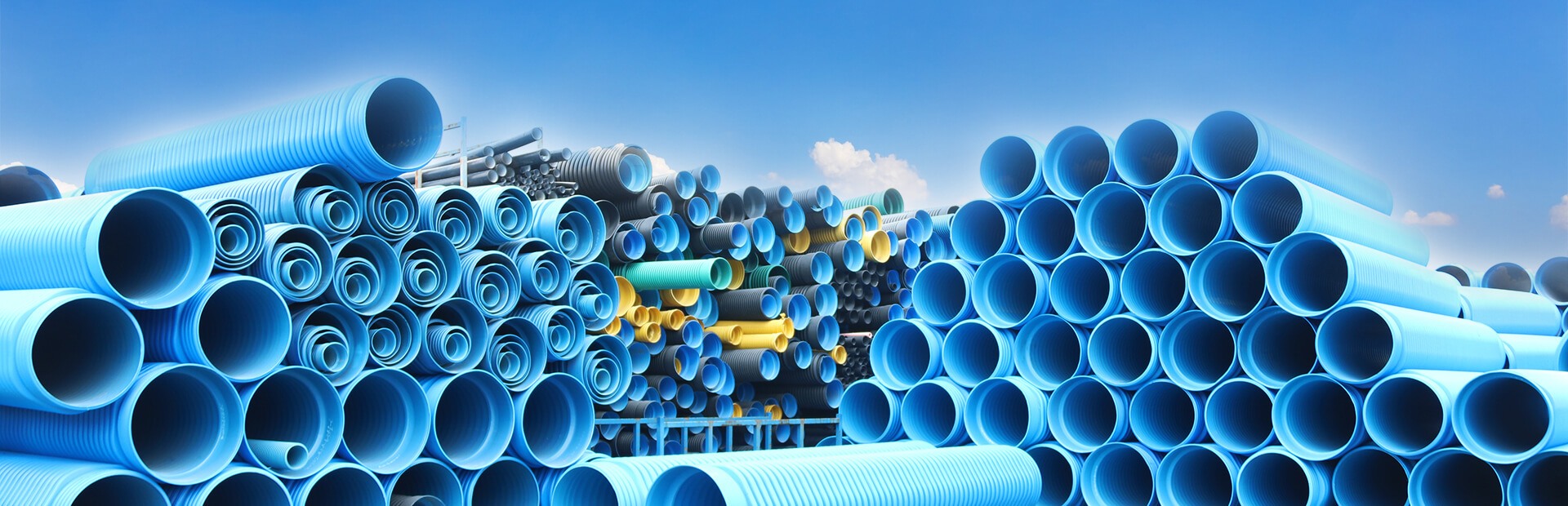

Nano-modified high-density polyethylene alloy drainage pipe

Nano-modified high-density polyethylene alloy drainage pipes utilize ultra-high molecular weight polyolefins, ultra-high molecular weight copolymer compatibilizers, nano-reinforcement agents, and special anti-aging additives. The material modification is carried out using the globally leading reciprocating single-screw extruder from Swiss BUSS company, and the alloy pipes are extruded using a fully automatic ultra-high-speed alloy pipe production line.

Classification:

Detailed description

Product Introduction

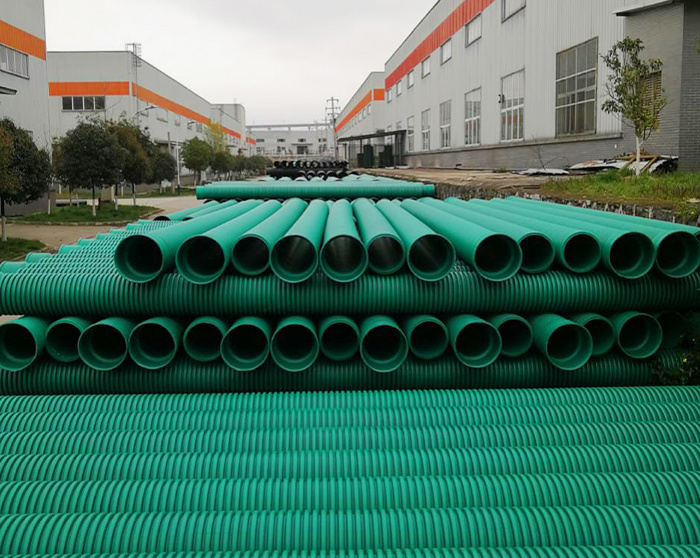

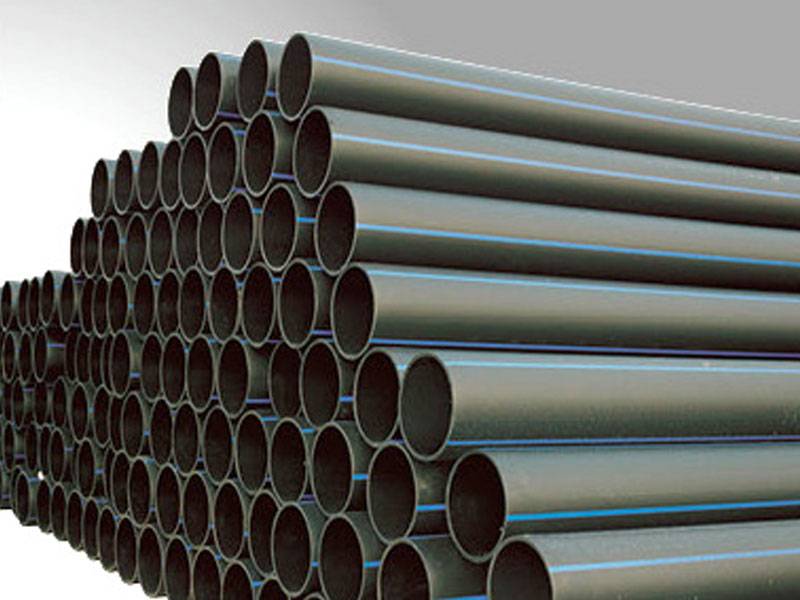

Nano-modified high-density polyethylene alloy drainage pipes utilize ultra-high molecular weight polyolefins, ultra-high molecular weight copolymer compatibilizers, nano-reinforcement agents, and special anti-aging additives. The materials are modified using the world's leading reciprocating single-screw extruder from BUSS in Switzerland, and the alloy pipes are extruded using a fully automatic ultra-high-speed alloy pipe production line. The nano-modified high-density polyethylene alloy drainage pipes use efficient compatibilizing materials and innovative formulation design through interfacial reaction compatibilization methods to solve the interfacial compatibility between ultra-high molecular weight polyolefins and nano-reinforcement agents. By toughening and compatibilizing, they achieve ultra-high strength, high rigidity, high toughness, and aging resistance in nano-alloy materials. This improves the product's rigidity, creep resistance, smoothness of the inner wall, resistance to point load failure, impact resistance, and ring flexibility.

The nano-modified high-density polyethylene alloy drainage pipes have undergone drop impact tests, ring stiffness tests, ring flexibility tests, xenon arc lamp tests, ultraviolet fluorescent lamp tests, carbon arc lamp accelerated aging tests, ultra-high load tests after landfill, excavator point contact tests, excavator on-site compaction tests, and excavator sand impact tests conducted by national authoritative testing institutions.

Implementation Standard: T/GZHG 002-2017 "Nano-modified High-Density Polyethylene (MUHDPE) Alloy Pipe"

Main Application Areas of the Product

◎ Mainly used in municipal engineering for road sewage and rainwater pipes, urban sewage treatment plant pipeline projects, urban utility tunnels, highways, high-speed railways, bridge drainage projects, rural rainwater and sewage diversion projects, pollution control projects, flood discharge projects, power station drainage networks, culverts, and other fields.

Physical and Mechanical Performance Index Requirements for Raw Materials of Nano-modified High-Density Polyethylene Alloy Drainage Pipes

| Serial Number | Item | Unit | Index | Test Method |

| 1 | Ash Content | % | ≤ 30 | 6.4.1 |

| 2 | Tensile Strength | Mpa | ≥ 22 | 6.4.2 |

| 3 | Elongation at Break | % | ≥ 300 | 6.4.2 |

| 4 | Bending Modulus | Mpa | ≥ 1250 | 6.4.3 |

| 5 | MFR (Melt Flow Rate) | g/10min | ≤ 3 | 6.4.4 |

Physical and Mechanical Performance Index Requirements for Nano-modified High-Density Polyethylene Alloy Drainage Pipes

| Serial Number | Item | Unit | Index | Test Method | |

| 1 | Ring Stiffness | SN12.5 | 2KN/m | ≥ 12.5 | 6.4.5 |

| 2 | Drop Impact Test | - | 10/10 Passed | 6.4.6 | |

| 3 | Ring Flexibility | - | Outer diameter deformation reaches 40%, sample is smooth with no reverse bending or cracking; no separation of walls. | 6.4.7 | |

| % | Outer diameter deformation reaches 40%, recovery rate of pipe deformation after ring flexibility test is measured one hour later; inner diameter retention rate before and after testing is greater than 95%. | 6.4.7 | |||

| 4 | Oven Test | - | No bubbles, no delamination, no cracking. | 6.4.8 | |

| 5 | Creep Ratio | % | <= 4 | 6.4.9 | |

| 6 | OIT Oxidation Induction Time | Min | > = 20 | 6.4.10 | |

Specifications and Prices

| Nominal Inner Diameter DN/ID | Minimum Average Inner Diameter Dim,min | Minimum Laminated Wall Thickness emin | Minimum Inner Layer Wall Thickness e1,min | Minimum Joint Length Amin | (Socket) Wall Thickness e2 | (kN/m2) Ring Stiffness | (Yuan/m) Price |

| 200 | 195 | 2.0 | 1.1 | 54 | 2.5 | SN12.5 | 145.00 |

| 300 | 294 | 2.5 | 1.7 | 64 | 3.0 | SN12.5 | 285.00 |

| 400 | 392 | 3.0 | 2.3 | 74 | 3.5 | SN12.5 | 456.00 |

| 500 | 490 | 3.5 | 3.0 | 85 | 4.0 | SN12.5 | 722.00 |

| 600 | 588 | 4.0 | 3.5 | 96 | 5.0 | SN12.5 | 1000.00 |

| 800 | 785 | 4.5 | 4.5 | 118 | 6.5 | SN12.5 | 1700.00 |

| 1000 | 985 | 6.0 | 5.0 | 140 | 8.0 | SN12.5 | 3080.00 |

| 1200 | 1185 | 8.0 | 5.5 | 162 | 9.0 | SN12.5 | 4790.00 |

| 1500 | 1485 | 10.0 | 6.5 | 178 | 10.0 | SN12.5 | 6288.00 |

Key words:

Senrui pipeline, Guiyang pipeline manufacturer

Related Products

Complaint recommendations

Note: Please fill in the above information correctly so that we can feedback the processing results to you at the first time!